Craftsmanship

Japanese Craftsmanship・Committed to Made in Japan

Presage presents a unique Japanese aesthetic to the world.

In particular, the uniqueness of the materials of its dials cannot be expressed without the advanced techniques and commitment of craftsmen. The Made in Japan quality reflects Seiko’s history of watchmaking, as well as the techniques and passion of the craftsmen.

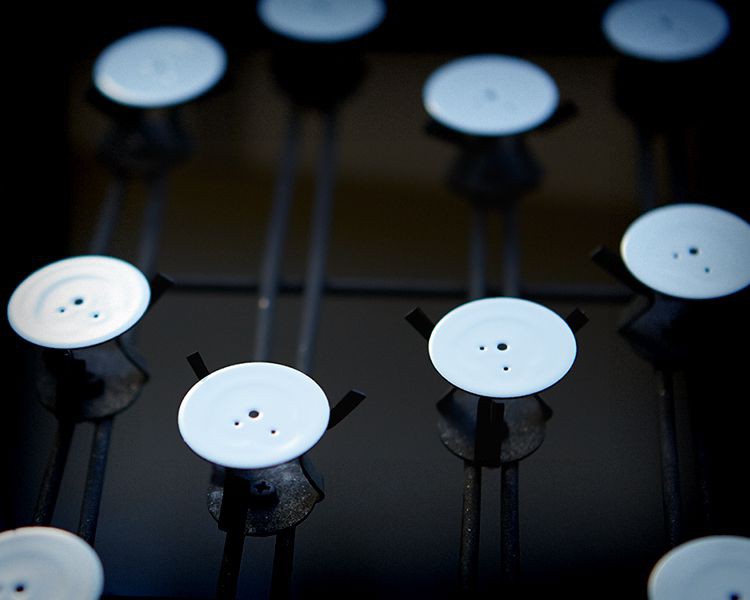

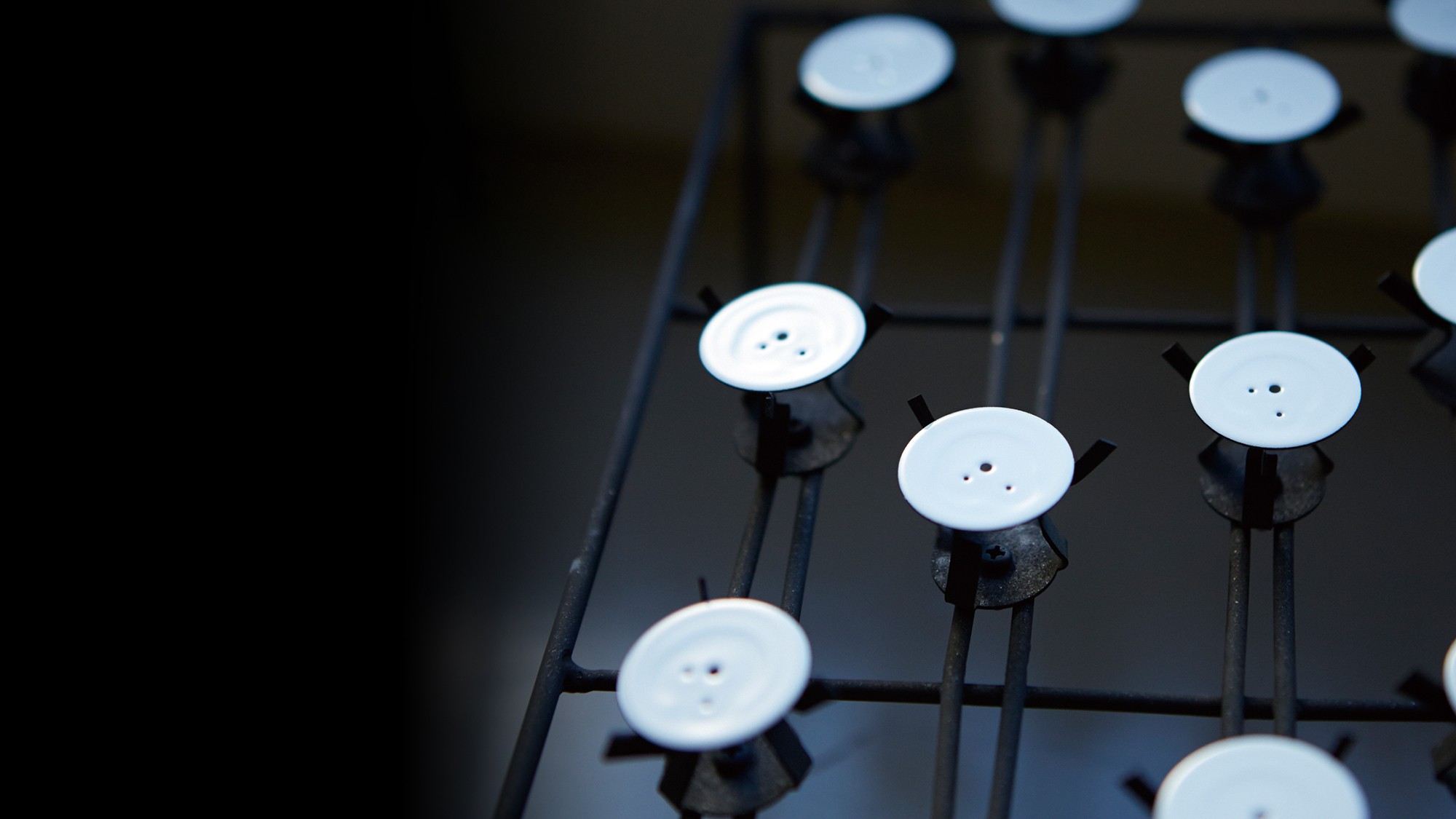

Enamel Dial

The enamel dial was also used for the Laurel, Japan’s first wristwatch. The texture of enamel captures a feeling of warmth from its unique, soft sheen. The dial appearance that retains its beautiful color tones that continue to delight the eyes of the wearer.

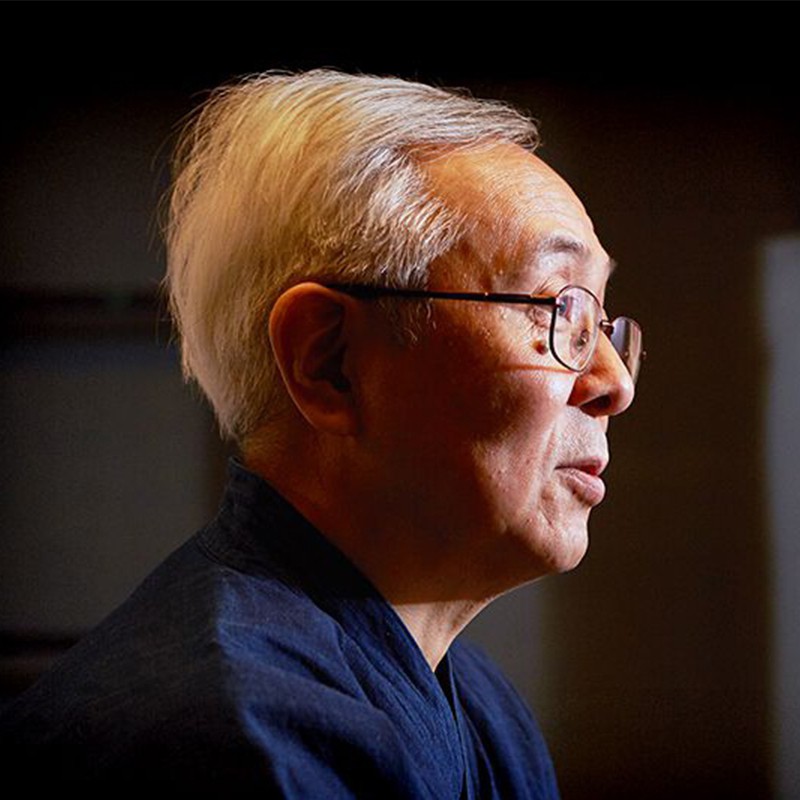

Enamel Craftsman: Mitsuru Yokosawa

For almost half a century, Mitsuru Yokosawa has been expanding the

boundaries of enamel, mastering time-honored techniques and gradually creating new ones. As his experience broadened, the layers of enamel he was able to apply became thinner and thinner. He is now able to apply a flawless enamel coat just 0.1 mm thin. Such precision requires not only exceptional visual acuity, but also the seemingly magical ability to make minute adjustments to the enamel composition based on fluctuations in humidity and weather conditions. Aptly, it would take the skills of a magician to create the face of the new Seiko Presage.

Artisan of Time: Enamel Craftsman

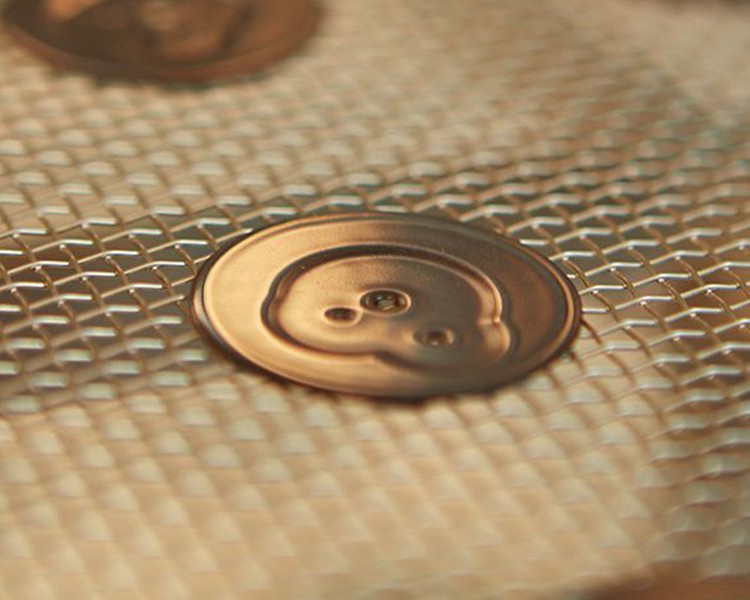

Urushi Dial

An Urushi dial created by applying multiple layers of lacquer made from the sap of the Urushi tree. It features a glossy deep black color, which is the origin of the word “shikkoku” (Urushi black).

Lacquer Artist: Isshu Tamura

Born in 1957, Isshu Tamura trained in the traditional Kaga Maki-e gold lacquer technique of Kanazawa. After honing his skills in the technique, Mr. Tamura set out to produce unparalleled original works of art. He has executed his technique in Kaga Maki-e not only in lacquerware, but also in the creation of luxury fountain pens and wristwatches which have received worldwide acclaim for their elaborate detail and fine beauty.

The Artisan of Time: Lacquer Artist

Urushi

First, the dials are made with the traditional Urushi technique in which jet black lacquer is painted by hand onto the metal base of the dial, dried and then polished. These processes are repeated several times until the craftsman has achieved the exact depth of black that he desires.

Byakudan-nuri

Using a new layer of Urushi as the binding agent, the sub-dials are then sprinkled with a layer of very fine metallic powder. The whole dial is then repeatedly painted with a red-tinged semi-transparent Urushi lacquer and then each new layer is dried and polished for as many times as the craftsman deems necessary. The effect is subtle but deeply satisfying. While the red of the sub-dials is deep, these two dials catch the light and shine when the ambient light grows brighter, just as parts of the sky catch the dawn light before others.